Center of Excellence for Industrial Automation

Training | Development | Consultancy

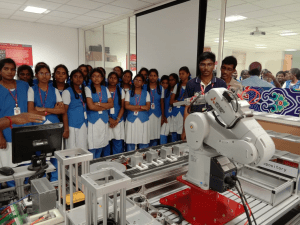

The Industrial Robotics and Automation centre was established to offer training on robots and its applications in an industrial calibre. This Centre of Excellence was setup in Collaboration with KUKA, Germany in 2014, which houses one of the best Kuka’s articulated arms, the KR – 16, where the students are taught to simulate and program the robot to perform stipulated tasks

The training is split into three tiers – Beginner, Advanced and Expert.

The Beginner level enables a student to understand the need of robots in industries, its basic operations and an introduction to simulation.

The Advanced level training gives the student a detailed overview of simulation and calibration of the robot along with introducing the robot teaching methods.

The Expert level training focuses more on hardware disassembly and reassembly, an in-depth study about controllers and robot programming.

The outcome of the course is to enable the student with the knowledge and confidence to not limited to Kuka robots but also on other articulated arms and robots of industrial standard.

The centre was further expanded with Industrial Automation facility in 2017 in Collaboration with Tianjin University, China and Mitsubishi Robots housing 4 Industrial graded Mitsubishi Robotos and automation infrastructure to impart practical knowledge about automation and gives exposure to industrial practices.Training on various platforms like PLC programming, Pneumatic circuits designing, prototype modelling and micro bot programming are offered at various levels.

The training is split into 2 levels.

The initial phase focuses on giving an in-depth knowledge on the basics of sensors, actuators and its calibration and interfacing techniques. This is accomplished by letting the students work on prototype modelling kits like lego mindstorm, abilix, and c6 creative bricks, which provides the students the confidence and requisite knowledge to work on much complex systems.

The second phase focusses on making students work on industry ready systems. The key element of this laboratory is a one of the kind customisable automation setup. The setup comprises of an industrial grade articulated robotic arm Mitsubishi Melfa RV4FLD for programming and Mitsubishi PLC to automate the process.The Students are given an overview of employing robots in automation sequences. The outcome of the training paves worthy practical exposure to work on complex automation setups and sequences on an industrial grade.

Various Industrial consultancy projects and solutions are offered as service at this centre attracting Industrial attention, product development and startups. Notable achievements have been made by students from the CoE at national and international skill competitions grabbing the attention of the global education fraternity.

Centers of Excellence

- CIT – Atalon Engine Research Center

- IIT Bombay Remote Center

- Center for 3D Printing and Reverse Engineering

- CIT – KYUTECH – WABCO Center for IoT

- Center for Data Science & Research

- Center for Nanotechnology

- Center for Biomedical Engineering and Research

- CISCO Networking Academy

- Center for Hi-Tech Hydroponics R & D

- HCL Center for Embedded and Imaging Technology

- MoE’s – Institution Innovation Council

- Center for NC Technologies

- T&VS Center for VLSI Design

- Center for Industrial Automation

- Accurate Center for Metrology

- KUKA Center for Industrial Robotics

- Harita Research Center in Mechanical Engg.

- PMKVY Skill Development Center

- PEGA University Academic Program

- Tekla Center for Buildings Education